This is a long one, apologies for the delay in posting, it has been quite the journey. This post will be better viewed in the app or on your browser.

Where do I start…

I am home.

I landed back in Blighty a couple of days ago. I am tired, transitioning, and still cleaning the dust from my body.

My heart is full but my mind is dancing, in the background, I am slowly writing a comprehensive article on the trip, however, this will take some time.

Travel is tough on the body but even more so on the mind, romantic ideas of far-flung exotic destinations have no place here, this is not a 5* luxury resort with an organised visit to see some trees, this is work, hard work, rewarding work, and a very much needed reminder of just how complex the coffee landscape can be…

I land in Kigali around 6 pm, 29 hours after leaving home, I feel the wall of heat embrace me as I descend from the plane, I have finally arrived. Bernice and Luke are there to greet me as I jostle through the arrivals terminal, their warm embrace is a much-needed transaction, we are heading to dinner with the family before we set off on the next leg of the journey, the farm awaits our arrival but beer is in order before we depart on another 5-hour trip by road.

I have 3 full days in Rwanda and we have a busy schedule ahead of us. I am here to work and I am itching to get started. We have an objective, an experiment, and the cherries were delivered to the washing station an hour ago, time is ticking. Why am I in East Africa again? Let me explain…

The Objective…

Relationships.

I have long been convinced that the only way to have any impact in this industry is through building, fostering, and maintaining strong relationships. I have said it before and I will say it again “ I truly want to know the humans that I am purchasing from” not because I have some weird trust issues but because I believe in shared objectives. I want to understand what is needed for our transactions to be beneficial for all involved, I want to understand if the things that are driving our industry are indeed viable, and I very much want to understand every detail of the journey from shrub to mug.

But Why?

1 - to gain a deeper appreciation of the process.

2 - to evaluate the potential for continued success.

3 - to understand the implications of our requests.

4 - to listen, to really listen.

5 - to learn, to really learn.

The list goes on…

The Experiment…

Yeast inoculation.

Over the next 3 days at Rwamatamu washing station, myself and team Rwamatamu carried out 4 main experiments. This was a joint project that had been in the planning stages for some time. The use of commercial yeast in coffee fermentation is a relatively new concept but one that is gaining significant traction and from personal experience is creating some interesting results. So when I was asked to be part of this small trial in Rwanda I jumped at the opportunity. This was a chance to put some theory into practice and the 4 trials looked like this:

Yeast inoculation on pulped coffee. (Dry)

Yeast inoculation on pulped coffee. (Submerged)

Yeast inoculation on cherry. (Dry)

Yeast inoculation on pulped grade B coffee. (Dry)

The idea of this post is to detail the individual stages of the experiment. Views, experiences and conclusions will come in later articles. A comprehensive pricing rundown will also be supplied, but for now, trust is in the process…

Delivery:

170kg of fresh cherry was delivered to Rwamatamu washing station from the Muduha district at 5 pm on 12/06/2023.

Cherry was paid for on delivery and left on a tarp, uncovered for 17 hours. Night temperature 15°C.

Sorting of cherries commenced at 11 am on 13/06/2023. It took 5 members of staff and myself 3 hours to hand-sort the cherry into class A cherries and class B cherries.

We also found a few culprits that are responsible for the dreaded POTATO defect that is widespread across Rwanda and other East African countries. The Antestia bug.

Once hand sorting had finished 20ltr buckets were filled with clean water and the cherries were then floated. This stage will remove any cherries that have no physical signs of defects. The less-dense cherries will float to the top and be skimmed away to be placed in the pile of Class B cherries. The causes of floating cherry are:

overripe, underripe, defected seeds, abnormal seed growth, and insect damage. Floating is another tool used to remove more defective coffee from the Class A pile.

The next step was to weigh out the final cherry weight for both Classes A cherry and B cherry. This would aid in our calculations for the individual Lot volume and provide us with the data needed to start preparing the yeast weights for rehydration.

From the total volume of cherries delivered, we ended up with a total of 110kg of Class A cherries and 60kg of Class B cherries. This gave us the numbers needed to weigh out the desired amount into their individual lots.

For this experiment, we are using two types of yeast for inoculation. Lalcafe Oro yeast and Lalcafe Intenso yeast. Both strains have been formulated for specific use in coffee fermentation and harness the naturally occurring and long-domesticated fungus known as saccharomyces cerevisiae which is also used in the wine, beer, and bread industries. Both yeasts have been modified to produce slightly different results when in fermentation.

LALCAFÉ INTENSO™ yeast’s specific metabolism facilitates rapid demucilagination and the release of varietal specific aromatic compounds. After years of studies run with different technical and research centers investigating coffee production and with results coming from trials performed in different wet mills around the world (in the Americas as well as Africa and Asia), LALCAFÉ INTENSO™ yeast (Saccharomyces Cerevisiae) has been characterized and selected for its ability to enhance coffee’s fruit character by releasing stone fruit, citrus, and floral notes as well as its ability to enhance mouthfeel in the final cup. The efficient demucilagination contributes to a more complex and higher quality sensory experience.

LALCAFÉ ORO™ yeast (Saccharomyces Cerevisiae) has been characterized and selected for its capabilities to optimize processing efficiency, enhance cup quality, and dramatically reduce defects. LALCAFÉ ORO™ offers control in a protective role as it out competes the indigenous flora and potential spoilage organisms for the available food thus ensuring consistency and quality through the fermenting coffee mass. LALCAFÉ ORO™ has been screened and characterized over a four-year period of research and trials. The results of the trials performed on Arabica and Robusta in different mills around the world (in Central America and South America as well as Africa and Asia) confirm that LALCAFÉ ORO™ is very well suited to controlling the fermentation process and as a result it can increase cup score and consistency. Its robustness, even at low temperature, ensures its good implantation in both cool and hot climates.

The individual Class A Cherry lots were then weighed out into 9 separate piles ready for pulping to commence.

The individual lot specifics are as follows:

Lot 1 Pulped (Submerged) 36.6kg

Lot 2 Pulped (Dry/Honey) 36.6kg

Lot 3 (Whole cherry/Natural) 36.6kg

We then got to work pulping Lots 1 & 2.

The light was starting to fade, but we needed to weigh out the pulped coffee weight. So, we got to work with speed, draining the water from the tubs and weighing out each batch individually. From a total weight of 73.2kg of cherry from the two lots that were pulped, we ended up with a total of 42 kilograms of pulped coffee. Just over 40% weight loss from cherry to pulp.

We did the sums and separated the pulped lots into 6 separate tubs containing 7kg of pulped coffee into each tub.

We then divided the whole cherry into 3 x 12.2kg lots and put them to rest in their tubs.

To make the experiment as valid as possible we decided to perform a control batch alongside each yeast-inoculated lot.

The next step was to weigh out and rehydrate the yeast needed for the inoculated lots:

Calculating the yeast dosage…

the recommended dosage was 1g of yeast to 1kg of pulped or whole cherry.

The lots looked like this:

7kg Control submerged - 7kg Intenso yeast submerged - 7kg Oro yeast submerged

= 7g Intenso yeast & 7g Oro Yeast.

7kg Control dry - 7kg Intenso yeast dry - 7kg Oro yeast dry

= 7g Intenso yeast & 7g Oro yeast.

12.2kg Control Cherry - 12.2kg Intenso yeast Cherry - 12.2kg Oro yeast Cherry

= 12.2g Intenso yeast & 12.2g Oro Yeast.

The yeast needed to be rehydrated for 30 minutes in a total volume of water that is 10 x the weight of yeast needed. This gave us ample time to divide the coffee into the correct tubs, label everything up, and calculate the amount of water needed for rehydration.

Submerged = 14g yeast = 140 ml of water

Dry = 14g yeast = 140 ml of water

Cherry = 24.4g yeast = 244 ml of water.

At the last minute and through multiple in-depth discussions throughout the day we decided to pulp the Class B cherries and apply the same protocol as detailed above. Our combined theory and discussions revolved around the proposed positive impacts that yeast could potentially have on a lower-grade of coffee cherry. We all agreed that this was a great opportunity to trial this theory so we weighed out the class B cherry which we pulped and added to our calculations for rehydration.

As night fell at Rwamatamu washing station, we tucked up the lots into their overnight accommodation, which was the green coffee storage warehouse. our hope was that the day’s sun would have sufficiently warmed up the store so that it would remain at consistent temperatures above 20°C. We had prepared for low night-time temperatures and the use of an insulated blanket was on hand if needed however, the team had been constantly monitoring the room temp over the previous 2 weeks and the temperature was safely maintaining readings well into to tolerances needed for the yeast to stay happy and active overnight.

The plan was to leave the coffee in fermentation for 24 hours and to start washing the following day. We finally got finished around 20:00 pm and with our brains ticking and ideas flowing we retired back to the farmhouse for a well-earned meal a glass of Skhol, and further reflection.

14/06/2023 - Day 2.

As we arrived at the washing station the team greeted us with excited enthusiasm and everyone was eager to take a look at the previous night’s work.

We started the morning with coffee and a team meeting, discussions revolved around coffee production in Rwanda and the ever-changing climate. There was mention of known coffee producers who were already trialling production with yeast and the pros and cons of implementing this protocol on a larger scale. We also discussed our observations from the process and how this differed from the current procedures. We took a stroll around the facility to take a look at the current infrastructure in place at Rwamatamu which involved an in-depth look at the waste management systems that were currently in place. We also spent time detailing the positive investment possibilities that would have the greatest impact on production efficiencies. Detailed notes were taken, and unanswered questions were documented, which will no doubt lead to further research. This was an incredibly passionate team who, from my very brief observations, are very proud of their work, proud of their coffee, and proud of Rwanda.

Once our morning meeting adjourned we all went to check on the lots.

Temperatures had been monitored at various points throughout the evening and the recommended 20°C had been achieved. As we popped the lids of the tubs for inspection we could clearly see that the fermentation was still very much active, The interesting things that were noted were just how active all of the lots had become, even the control. The one thing that really stood out to us was just how different all of the individual lots smelled. The control had a very much familiar smell of freshly pulped coffee but the Oro and Intenso lots were completely unfamiliar in their fragrance. The Oro lots seemed to have a bready almost beer-like fragrance and the Intenso lots were so pungent giving off heavy citrus and tropical vibes as soon as we popped the lids.

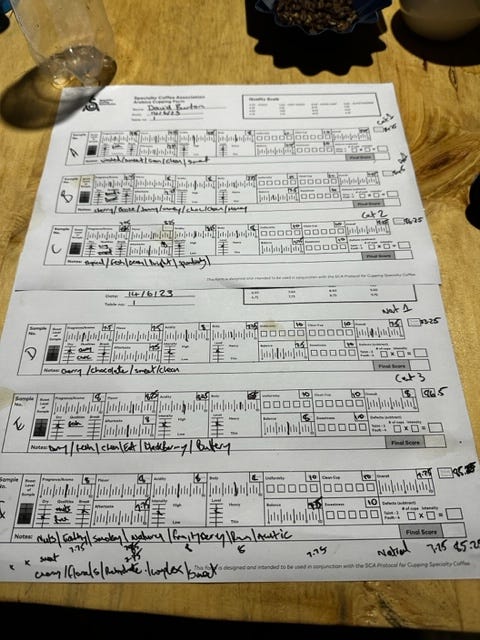

We were now 12 hours into fermentation and the rest of the day was set aside for some QC work. The harvest season in Rwanda was coming to an end and all of this year’s coffee had already finished drying.

The main objective was to grade the lots that had already been selected and to provide feedback on some of the experimental batches that Rwamatamu had trialled for the first time this year both Natural and Anaerobic lots.

Cupping in the country of production is always a privilege, and providing feedback on something that has taken a full year of hard work to produce is a slightly daunting task. I already knew Rwamatamu were producing excellent coffee from the results of the previous harvest but I was eager to see if this would be repeated this year.

This was an opportunity to calibrate with the team and provide some training on why it is important to connect the work in the field with the cupping results. It is also worth noting that every aspect of coffee production plays a significant role in what will end up in the final cup and being able to communicate this with a shared language is vital if we want to see quality improvements.

I am pleased to say that the coffee produced this year is again of excellent quality with some real standouts on the cupping table, especially the washed lots.

Washing and out to dry…

As the light started to fade on day 2 we checked our timings and one final check of the lots and it was decided that it was now time to wash and get the coffee onto the drying beds.

Fresh clean water was added to the batches and we hand-washed the pulped coffee to remove any mucilage that was still coating the seeds. We did notice a significant amount of the mucilage had been removed on all of the yeast-inoculated lots making this an easier task to wash compared to the control lots. This kind of makes sense as the yeast should be more efficient at consuming and converting more of the organic material available throughout the fermentation stage.

This was still no easy task and the process of washing the lots took a considerable amount of energy to be achieved, this took myself and 3 members of staff 2 hours to perform the task, this was another reminder of just how crucial it is to make sure all of the mucilage is removed and just how challenging this task is even at on a small scale.

Once the team were happy with the successful removal of the mucilage we hauled the tubs down to the pre-drying tables where the coffee would be spread out evenly for the night before they would need to be hand sorted the following morning and then finally left to dry for the next 20/25 days.

The time was once again late into the evening, we were all tired but energised from the collaborative experience. We had all learned a lot over the 2 days and we were excited about trying the end the results.

This will not conclude here however, I feel there are a few important takeaways. The first will be that this coffee along with all the effort will not be ready to evaluate for at least another 4/6 weeks.

As with all things, when you really get the opportunity to play an active role in the concept your ideas will be challenged throughout the whole process.

Do I still think Yeast will play an important role in the future of coffee production?

Do I still think experiments like this are essential for continued success?

Do I think we could have done things differently?

Do I think there are bigger issues that need evaluating other than quality?

Will this trip change my ideas on what is really important for the future of coffee production?

Do I even think the coffee will taste good?

I guess only time will tell…

Hey David. Welcome back!

Before I make any semi-rational/informed comment on this fascinating content, can I just say how thoroughly refreshing the positive affirmation you express for the coffee industry is, from in your words, 'shrub to mug'. If any industry had representatives of your personal quality in it, one couldn't help but feel it was in the safest of hands going forward, no matter the obstacles placed in its' way.

Meanwhile, back in Rwanda...the chemistry involved in your joint experimentation, whilst bewildering to many I'm sure (possibly just me!) displays how complex 'the bean' truly is and we amateur coffee aficianados can only marvel and be grateful for the effort that goes into such research. Laborious, but exciting! For what it's worth, I can only reiterate from previous comments, I hope that all processes undertaken, enhance/accentuate the anticipated characters of individual crops, although the odd 'surprise' could be considered complementary. Striving to maintain coffee excellence in all forms, must be paramount and in this ever changing ecosystem, your sterling efforts and all other significant players, will I'm certain, ensure the survival and advancement of our favourite beverage...